Table of Contents

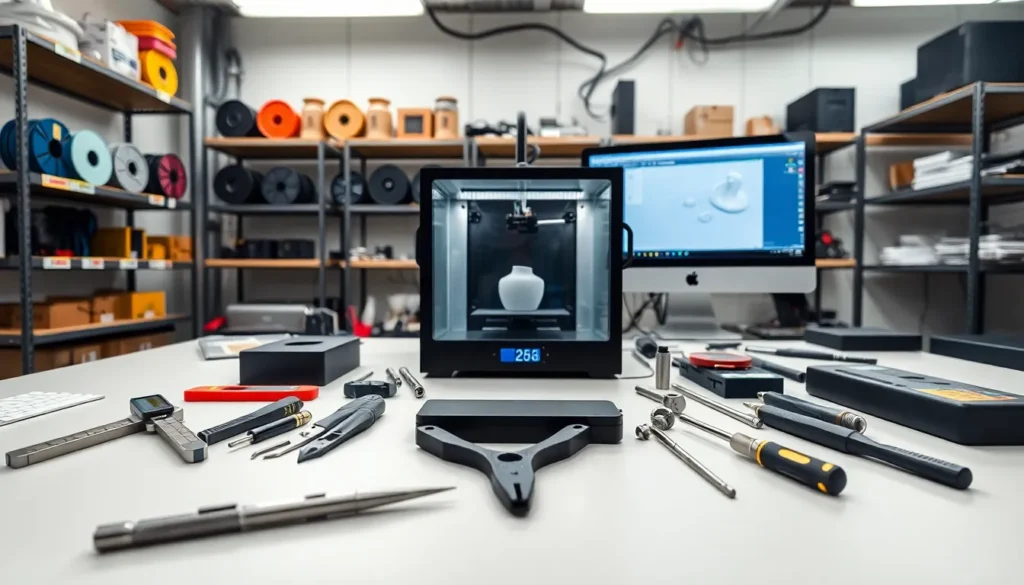

Toggle3D printing trends in 2026 are reshaping how industries build, design, and manufacture products. The technology has moved far beyond prototyping. Companies now use additive manufacturing for end-use parts, medical devices, and sustainable production at scale.

This year marks a turning point. Multi-material printers produce complex components in single runs. AI software optimizes designs before machines start printing. New biodegradable materials replace traditional plastics. Hospitals print patient-specific implants with growing precision.

These advances aren’t theoretical, they’re happening now. This article covers the most significant 3D printing trends 2026 has brought to manufacturing, healthcare, and sustainability.

Key Takeaways

- 3D printing trends 2026 show the technology expanding beyond prototyping into end-use manufacturing, healthcare, and sustainable production at scale.

- Multi-material and metal 3D printing now deliver industrial-grade precision with faster build speeds and lower costs than ever before.

- AI-driven design tools and real-time monitoring systems are automating workflows and reducing failed prints significantly.

- Sustainable practices are advancing through recycled materials, biodegradable polymers, and localized production that cuts waste and emissions.

- Healthcare applications are surging, with hospitals routinely printing surgical guides, custom implants, and even patient-specific medications.

- Regulatory frameworks have matured, giving medical device companies clearer compliance pathways for 3D printed products.

Advances in Multi-Material and Metal Printing

Multi-material 3D printing has become a standard capability rather than a premium feature. Printers now combine polymers, metals, ceramics, and composites within single builds. This shift allows manufacturers to create functional parts that previously required assembly from multiple components.

Metal 3D printing costs have dropped significantly. Binder jetting and directed energy deposition systems now produce parts at prices competitive with traditional casting. Aerospace companies use these methods for turbine components. Automotive manufacturers print lightweight structural parts. Tool makers produce custom dies without months of lead time.

The precision of metal printing has improved as well. Layer resolutions below 50 microns are now common for industrial systems. Surface finishes require less post-processing. Mechanical properties match or exceed those of wrought materials in many applications.

3D printing trends 2026 show particular growth in gradient materials. These parts transition smoothly from one material composition to another. A single component might feature a hard exterior with a flexible core. This capability opens design possibilities that conventional manufacturing cannot match.

Companies also report faster build speeds. New laser systems and print head arrays have doubled throughput compared to 2024 equipment. What once took days now finishes in hours. This speed makes 3D printing viable for medium-volume production, not just prototypes or specialty parts.

AI-Driven Design and Manufacturing Automation

Artificial intelligence has transformed how engineers approach 3D printing design. Generative design software now creates optimized structures that humans wouldn’t conceive. These algorithms analyze stress patterns, weight requirements, and material constraints. They then produce organic-looking geometries that perform better while using less material.

AI handles more than design. Machine learning systems now monitor prints in real time. Cameras and sensors detect defects as layers form. The software adjusts parameters automatically, laser power, feed rates, temperature profiles. Failed prints have become less common. Quality control happens during production rather than after.

3D printing trends 2026 include significant advances in automated post-processing. Robotic systems remove support structures. Automated finishing cells handle sanding, polishing, and coating. The entire workflow from design file to finished part requires minimal human intervention.

Slicing software has grown smarter too. AI algorithms optimize tool paths for speed and quality. They predict potential issues and adjust print strategies accordingly. What once required expert knowledge now happens automatically behind the scenes.

Digital twins connect physical printers to virtual models. Engineers simulate builds before committing materials. They identify problems, test variations, and refine processes without wasting resources. This approach reduces trial-and-error significantly and speeds new product development.

Sustainable Materials and Eco-Friendly Practices

Environmental concerns have pushed 3D printing toward greener practices. Recycled materials now work reliably in many printer systems. Post-consumer plastics become new filaments. Metal powders get reclaimed and reused across multiple builds.

Biodegradable polymers have expanded beyond PLA. New plant-based materials offer better mechanical properties. Some break down in industrial composting facilities within months. Others decompose in home compost bins. These options appeal to companies with sustainability targets.

3D printing trends 2026 emphasize waste reduction as a core benefit. Additive manufacturing uses only the material needed for each part. Traditional machining might waste 80% of raw stock as chips and shavings. 3D printing reverses this ratio. Most powder or resin becomes finished product.

Energy consumption has improved as well. Newer systems use more efficient heating elements and lasers. Build chambers retain temperature better. Some facilities now power their printers entirely with renewable electricity.

Local production reduces shipping distances. Companies print parts near end users instead of shipping from centralized factories. This distributed manufacturing model cuts transportation emissions. It also speeds delivery times and reduces inventory costs.

Material suppliers have responded to demand for transparency. Certifications verify recycled content and sustainable sourcing. Carbon footprint data accompanies material specifications. Buyers can make informed choices based on environmental impact.

Growth in Healthcare and Bioprinting Applications

Healthcare represents one of the fastest-growing sectors for 3D printing in 2026. Hospitals now print surgical guides as routine practice. Custom implants match patient anatomy precisely. Dental labs produce crowns, bridges, and aligners faster than ever.

Bioprinting has moved from research labs toward clinical application. Scientists print tissue structures using living cells. Skin grafts for burn victims enter early trials. Cartilage replacements show promise in joint repair. Full organ printing remains years away, but progress accelerates.

3D printing trends 2026 show significant activity in pharmaceutical manufacturing. Some facilities print pills with customized drug combinations and release profiles. Patients receive medications formulated specifically for their needs. Dosages adjust based on weight, metabolism, and other factors.

Prosthetics and orthotics benefit from additive manufacturing’s customization capabilities. Limb sockets fit better because they’re built from patient scans. Costs have dropped dramatically. Children who outgrow devices quickly can receive affordable replacements.

Medical device companies use 3D printing for complex internal geometries. Porous surfaces on implants encourage bone integration. Lattice structures reduce weight while maintaining strength. These features would be impossible or prohibitively expensive with traditional manufacturing.

Regulatory frameworks have caught up with the technology. FDA guidance now addresses additive manufacturing specifically. Cleared devices using 3D printing have multiplied. Hospitals understand the compliance pathway better than in previous years.