Table of Contents

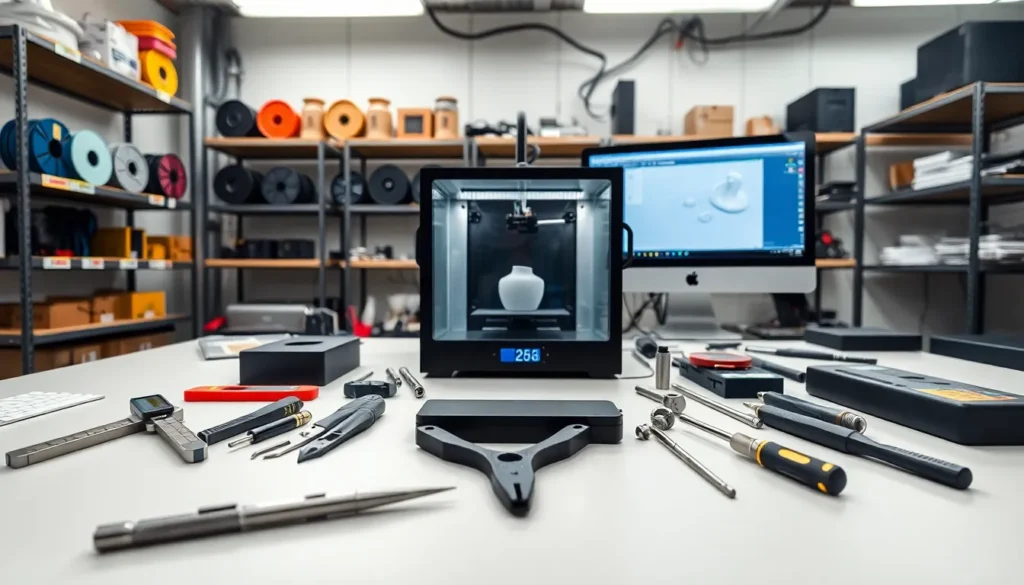

Toggle3D printing examples now span nearly every major industry, from life-saving medical devices to custom sneakers. This technology has moved far beyond hobbyist projects and prototype models. Companies worldwide use additive manufacturing to produce functional parts, reduce costs, and speed up production timelines.

The numbers tell a clear story. The global 3D printing market reached $18.3 billion in 2024 and continues to grow at roughly 20% annually. Major manufacturers, hospitals, and research institutions have adopted this technology because it solves real problems. It creates parts that traditional manufacturing cannot produce. It cuts waste. It enables rapid iteration.

This article explores practical 3D printing examples across six sectors. Each section highlights specific use cases, real companies, and measurable benefits. Whether someone works in healthcare, aerospace, construction, or education, these examples demonstrate how additive manufacturing delivers tangible results.

Key Takeaways

- 3D printing examples now span healthcare, aerospace, automotive, construction, consumer products, and education, proving the technology’s versatility across industries.

- Medical applications include custom prosthetics costing under $50, surgical planning models that reduce surgery time by 25%, and FDA-approved titanium implants.

- Aerospace giants like GE Aviation and Boeing use 3D printed parts to reduce weight, cut costs by millions, and improve component durability.

- 3D printed construction can reduce labor by 70% and building costs by 30-40%, with companies like ICON producing entire homes in under 48 hours.

- Major brands such as Adidas, BMW, and Invisalign use additive manufacturing for mass production, not just prototyping.

- Rapid prototyping with 3D printing enables product teams to iterate dozens of designs quickly, reducing development costs from thousands of dollars to cents per prototype.

Healthcare and Medical Applications

Healthcare provides some of the most impressive 3D printing examples available today. Medical professionals use this technology to create patient-specific devices that improve outcomes and reduce surgical complications.

Custom Prosthetics and Orthotics

Traditional prosthetic limbs require weeks of fitting and adjustment. 3D printed prosthetics can be designed, produced, and delivered in days. Organizations like e-NABLE have provided thousands of free 3D printed hands to children worldwide. These devices cost a fraction of conventional prosthetics, sometimes under $50 for materials.

Adult prosthetics have advanced even further. Companies now produce 3D printed legs with integrated sensors and adjustable components. Patients receive limbs matched precisely to their anatomy from digital scans.

Surgical Planning Models

Surgeons use 3D printed anatomical models to plan complex procedures. Before operating on a patient’s heart or skull, a surgeon can hold an exact replica in their hands. Hospitals report that these models reduce surgery time by 25% on average. Shorter procedures mean lower infection risk and faster recovery.

Bioprinting and Implants

Researchers have successfully 3D printed living tissue samples using bioinks made from human cells. While full organ printing remains years away, scientists have created functional skin grafts, cartilage, and bone scaffolds. Titanium 3D printed implants are now FDA-approved and used in spinal fusion surgeries and hip replacements.

Dental Applications

Dentistry has embraced 3D printing enthusiastically. Clear aligners, crowns, bridges, and surgical guides are now routinely 3D printed. Invisalign produces over 500,000 unique aligners daily using additive manufacturing. This 3D printing example shows how mass customization becomes economically viable.

Aerospace and Automotive Manufacturing

Aerospace and automotive companies were early adopters of industrial 3D printing. These sectors demand lightweight, high-performance parts, exactly what additive manufacturing delivers.

Aircraft Components

GE Aviation 3D prints fuel nozzles for its LEAP jet engines. Each nozzle previously required 20 separate parts welded together. The 3D printed version is a single piece that weighs 25% less and lasts five times longer. GE has produced over 100,000 of these nozzles since 2016.

Boeing uses 3D printed titanium parts in its 787 Dreamliner. The company reports saving $3 million per aircraft through weight reduction and simplified assembly. Airbus has installed over 1,000 3D printed components in its A350 aircraft.

Automotive Innovation

Formula 1 teams rely heavily on 3D printing examples for rapid development. McLaren produces hundreds of prototype parts weekly during racing season. Wind tunnel models that once took weeks now arrive in hours.

Production vehicles increasingly contain 3D printed parts. BMW produces over 300,000 3D printed components annually, including customized interior elements and manufacturing tools. Porsche offers 3D printed bucket seats that customers can configure for their exact body shape.

Tooling and Fixtures

Manufacturers save significant money by 3D printing jigs, fixtures, and assembly tools. Ford reduced the cost of one assembly tool from $1,000 to $100 by printing it in-house. Production timelines dropped from weeks to hours. These 3D printing examples prove the technology works beyond final parts.

Architecture and Construction

Construction represents one of the fastest-growing areas for 3D printing examples. Large-scale printers now produce entire buildings, while architects use smaller machines for detailed models.

3D Printed Buildings

ICON, a Texas-based company, has 3D printed dozens of homes in the United States and Mexico. Their Vulcan printer deposits concrete layer by layer, creating a complete house shell in under 48 hours. A community of 100 3D printed homes is under construction in Georgetown, Texas.

In the Netherlands, a family moved into Europe’s first 3D printed house in 2021. The boulder-shaped concrete structure met all building codes and demonstrates that printed buildings can be architecturally interesting, not just functional.

Cost and Speed Advantages

3D printed construction reduces labor requirements by up to 70%. Material waste drops significantly because printers deposit only what’s needed. ICON reports that their printed homes cost 30-40% less than traditionally built equivalents.

Speed matters too. Habitat for Humanity partnered with Alquist 3D to print affordable homes in Virginia. Each house took just 12 hours of active print time. This efficiency addresses housing shortages in ways conventional construction cannot match.

Architectural Models

Architects have used 3D printing for years to create detailed scale models. Complex geometries that would take model makers weeks to build emerge from printers overnight. Clients can hold physical representations of proposed buildings, making design decisions faster and more informed.

Consumer Products and Fashion

Consumer goods offer creative 3D printing examples that demonstrate the technology’s versatility. From footwear to furniture, companies create products that traditional manufacturing cannot replicate.

Athletic Footwear

Adidas sells running shoes with 3D printed midsoles. Their 4DFWD line uses lattice structures optimized through simulation to provide specific cushioning properties. Each midsole contains thousands of precisely positioned struts that guide energy forward. New Balance and Under Armour have introduced similar products.

Carbon, the 3D printing company behind Adidas’s technology, produces millions of shoe components annually. This scale shows that 3D printing has moved beyond prototyping into genuine mass production.

Eyewear

Luxury eyewear brands increasingly offer 3D printed frames. The technology enables shapes impossible to manufacture through injection molding. Customers can order glasses customized to their facial measurements. Some companies scan a customer’s face and deliver perfectly fitted frames within days.

Home Goods and Furniture

Designers create furniture with organic forms that celebrate what 3D printing makes possible. Chairs, lamps, and decorative objects feature intricate patterns and hollow structures. Dutch designer Dirk van der Kooij produces furniture from recycled plastic using a modified industrial robot.

Jewelry

Jewelers use 3D printing to create wax patterns for casting or to print directly in precious metals. Complex geometries that would require hours of hand work emerge from printers ready for finishing. Custom engagement rings can move from design to final product in days rather than weeks. These 3D printing examples show how personalization becomes practical at any scale.

Education and Prototyping

Education and product development benefit enormously from accessible 3D printing examples. The technology transforms how students learn and how companies bring products to market.

K-12 and University Programs

Schools at every level now include 3D printing in their curricula. Elementary students design simple objects and watch them materialize. High schoolers tackle engineering challenges with immediate physical feedback. Universities operate advanced printing labs where students explore materials science, mechanical engineering, and industrial design.

Anatomy classes use 3D printed models that students can handle and examine from every angle. History students recreate artifacts. Art students push creative boundaries. The hands-on experience reinforces concepts in ways that textbooks and videos cannot.

Rapid Prototyping

Product development teams rely on 3D printing to test ideas quickly. A designer can create a concept in CAD software, print it overnight, and evaluate it the next morning. This speed enables dozens of iterations where traditional methods might allow only a few.

Consumer electronics companies print hundreds of case designs before committing to tooling. Medical device firms test ergonomics with realistic prototypes. Toy companies evaluate playability before investing in molds. The iteration cost drops from thousands of dollars to mere cents per prototype.

Functional Testing

Advanced 3D printing materials enable functional prototypes, not just visual models. Engineers print gears that actually mesh, hinges that flex, and snap-fits that work. Some printed plastics mimic the properties of production materials closely enough for meaningful testing. These 3D printing examples accelerate development cycles across industries.