Table of Contents

Toggle3D printing vs traditional manufacturing presents a choice that affects cost, speed, and product quality. Businesses and hobbyists face this decision more frequently as additive manufacturing technology advances. Traditional methods like injection molding and CNC machining have dominated production for decades. Yet 3D printing now offers compelling advantages for specific applications. This guide breaks down both approaches across key factors, cost, speed, materials, and ideal use cases, so readers can make an well-informed choice for their next project.

Key Takeaways

- 3D printing vs traditional manufacturing depends primarily on production volume—3D printing wins for 1-100 units, while traditional methods become cost-effective at 1,000+ units.

- 3D printing eliminates expensive tooling costs ($10,000-$100,000 for injection molds), making it ideal for prototyping and low-volume production.

- Traditional manufacturing delivers faster ongoing production rates (15-60 seconds per part vs. 2-20 hours for 3D printing) and superior consistency at scale.

- 3D printing offers unmatched design freedom for complex geometries, internal channels, and customized products like dental aligners and prosthetics.

- Many manufacturers combine both approaches—using 3D printing for prototypes and bridge production while preparing traditional tooling for full-scale manufacturing.

How 3D Printing Works Compared to Traditional Methods

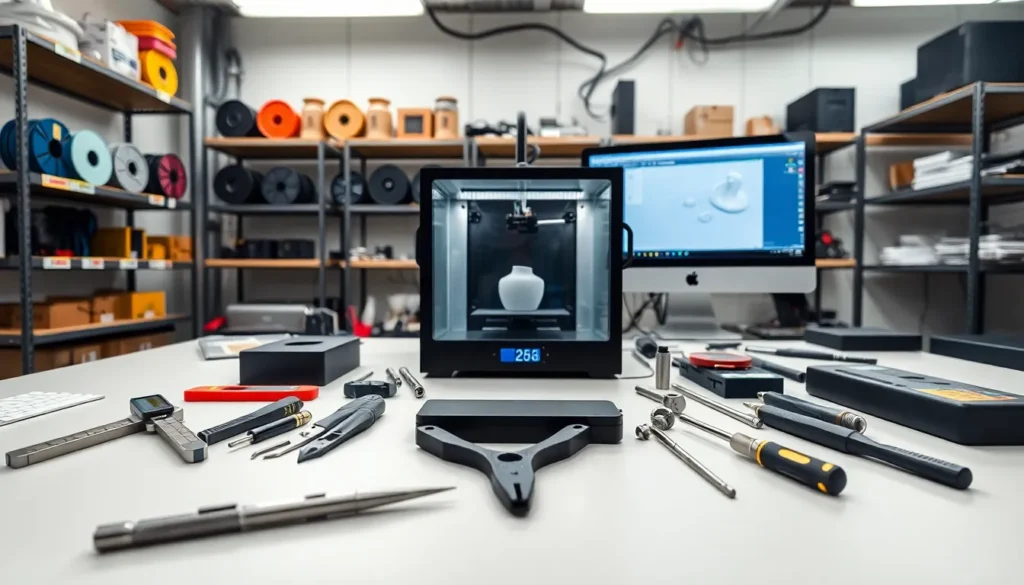

3D printing builds objects layer by layer from digital files. A printer reads a CAD model, slices it into thin horizontal sections, and deposits material one layer at a time. This additive process uses only the material needed for the final part.

Traditional manufacturing takes the opposite approach. Subtractive methods like CNC machining start with a solid block and cut away material. Formative methods like injection molding force heated material into pre-made molds.

3D printing vs conventional production differs fundamentally in setup requirements. Traditional manufacturing demands tooling, molds, and fixtures before production begins. A single injection mold can cost $10,000 to $100,000. 3D printing skips this step entirely, send a file to the printer and production starts.

The technical process also affects design freedom. Traditional methods impose constraints. Undercuts, internal channels, and complex geometries often require multiple parts or secondary operations. 3D printing handles these features in a single build. Engineers can design parts optimized for function rather than manufacturability.

But, traditional methods excel at consistency. Injection molding produces identical parts by the thousands with tight tolerances. 3D printing introduces layer lines and potential variations between builds. Each approach has strengths that suit different applications.

Cost Differences Between 3D Printing and Conventional Manufacturing

Cost calculations for 3D printing vs traditional manufacturing depend heavily on volume. At low quantities, 3D printing wins decisively. No tooling costs mean a single prototype might run $50 to $500 depending on size and material.

Traditional manufacturing front-loads expenses. That $50,000 injection mold spreads its cost across every part produced. At 100 units, each part carries $500 in tooling overhead. At 100,000 units, that drops to $0.50 per part.

Here’s where the crossover happens:

- 1-100 units: 3D printing typically costs less

- 100-1,000 units: Depends on part complexity and material

- 1,000+ units: Traditional manufacturing usually becomes cheaper

Material costs also differ. Industrial 3D printing materials like nylon or PEEK polymers cost $50-$500 per kilogram. Injection molding pellets run $1-$10 per kilogram. This gap narrows for metal 3D printing vs casting, but material expense remains a factor.

Labor costs favor 3D printing for small runs. Setup time for traditional methods, programming CNC machines, preparing molds, calibrating equipment, adds hours or days before the first part emerges. 3D printers require minimal setup once a file is prepared.

The 3D printing vs traditional cost equation shifts constantly as technology improves. Print speeds increase and material prices drop each year, moving that crossover point higher.

Speed and Production Volume Considerations

Speed in manufacturing has two components: time to first part and ongoing production rate. 3D printing dominates the first metric. A designer can finish a CAD model in the morning and hold a physical prototype by afternoon.

Traditional manufacturing requires weeks or months before producing the first unit. Tooling must be designed, machined, tested, and refined. Rush orders compress this timeline but inflate costs dramatically.

For 3D printing vs traditional methods in ongoing production, the picture reverses. An injection molding cycle takes 15-60 seconds per part. A 3D printer might need 2-20 hours for the same component. The math becomes stark at scale, traditional methods produce thousands of parts while a printer completes dozens.

Production volume targets guide the decision:

| Volume | Best Method | Reason |

|---|---|---|

| 1-50 | 3D Printing | No setup time |

| 50-500 | Either | Evaluate total cost |

| 500+ | Traditional | Higher throughput |

Some manufacturers combine both approaches. They use 3D printing for prototypes and bridge production while tooling is prepared. Once molds arrive, they switch to injection molding for full-scale manufacturing.

3D printing vs conventional production also differs in flexibility. Changing a 3D printed design means updating a file. Modifying injection molding requires new or altered tooling, a costly and time-consuming process. This agility makes 3D printing ideal for products still in development or customized items.

Material Options and Quality Outcomes

Material selection affects strength, appearance, and durability. Traditional manufacturing offers decades of tested material options. Thousands of plastic resins, metal alloys, and composites have established performance data.

3D printing materials have expanded rapidly but still lag behind. Common options include:

- PLA and ABS: Affordable plastics for prototypes and consumer products

- Nylon and PETG: Engineering-grade polymers with better durability

- Resins: Photopolymers offering fine detail for dental, jewelry, and medical models

- Metals: Titanium, stainless steel, and aluminum for functional parts

Quality outcomes differ between 3D printing vs traditional manufacturing. Layer lines remain visible on many 3D printed parts without post-processing. Injection molded parts have smooth surfaces straight from the machine.

Mechanical properties also vary. 3D printed parts often show anisotropic behavior, they’re stronger in some directions than others due to layer bonding. Traditionally manufactured parts typically have uniform strength throughout.

That said, 3D printing enables material combinations impossible with conventional methods. Multi-material printing places different polymers in the same part. Lattice structures reduce weight while maintaining strength. These capabilities open design possibilities that offset some quality limitations.

Surface finish matters for many applications. Traditional machining achieves tolerances of ±0.005 inches routinely. Consumer 3D printers manage ±0.1mm at best: industrial machines reach ±0.05mm. For precision applications, 3D printing vs traditional methods may require secondary finishing operations.

When to Choose 3D Printing Over Traditional Manufacturing

Certain scenarios clearly favor 3D printing:

Prototyping and product development represent the strongest use case. Designers iterate faster when changes cost nothing but time. A company developing a new product might print 20 versions before finalizing the design, an approach that would bankrupt most budgets using traditional tooling.

Custom and personalized products benefit from 3D printing’s per-unit economics. Dental aligners, hearing aids, and prosthetics now use 3D printing routinely. Each item differs from the last, and traditional manufacturing can’t match this flexibility economically.

Low-volume production under 500 units often makes 3D printing vs traditional manufacturing an easy choice. Tooling costs never amortize at these quantities. Specialty automotive parts, aerospace components, and industrial spare parts fit this category.

Complex geometries that traditional methods can’t produce economically push projects toward 3D printing. Internal cooling channels, organic shapes optimized through generative design, and consolidated assemblies all favor additive approaches.

Conversely, choose traditional manufacturing when:

- Volumes exceed 1,000 identical units

- Material requirements demand specific certifications

- Surface finish must meet exacting standards

- Part size exceeds available 3D printer build volumes

- Production timelines require thousands of parts daily

3D printing vs conventional production isn’t always an either-or decision. Many manufacturers maintain both capabilities, selecting the right tool for each project’s specific requirements.