Table of Contents

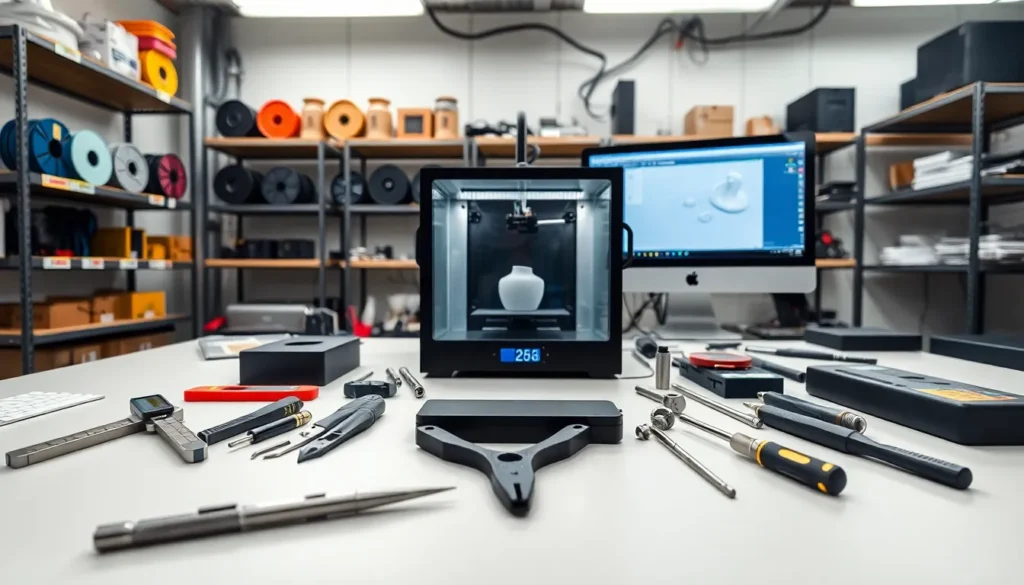

Toggle3D printing transforms digital designs into physical objects, one layer at a time. This technology, also called additive manufacturing, has reshaped industries from healthcare to aerospace. Unlike traditional manufacturing that cuts material away, 3D printing builds objects from the ground up.

Whether someone wants to create custom prototypes, replacement parts, or artistic sculptures, 3D printing offers a direct path from idea to reality. This guide breaks down how 3D printing works, the main technologies available, materials used, popular applications, and the key benefits and limitations beginners should understand.

Key Takeaways

- 3D printing builds physical objects layer by layer from digital designs, using materials like plastic, resin, or metal.

- FDM is the most beginner-friendly 3D printing technology, while SLA and SLS offer higher precision for professional applications.

- Popular 3D printing applications include rapid prototyping, healthcare (prosthetics, dental), aerospace, and custom consumer products.

- 3D printing enables design freedom, customization, and reduced material waste compared to traditional manufacturing.

- Limitations include slower production speeds for high volumes, visible layer lines, and size constraints on most consumer printers.

- Choosing the right material and technology combination is essential for successful 3D printing results.

How 3D Printing Works

3D printing starts with a digital file. Designers create this file using computer-aided design (CAD) software or by scanning an existing object with a 3D scanner. The software then slices the digital model into hundreds or thousands of horizontal layers.

A 3D printer reads these sliced layers and deposits material, usually plastic, resin, or metal, one layer at a time. Each layer bonds to the one below it. The process repeats until the printer completes the entire object.

Think of it like building a structure with LEGO bricks, except each “brick” is a thin sheet of material. The printer stacks these sheets precisely on top of each other.

Most consumer 3D printers take anywhere from 30 minutes to several hours to finish a print. Industrial machines can run for days on large projects. Print time depends on the object’s size, complexity, and the chosen layer resolution.

Once printing finishes, many objects require post-processing. This might include removing support structures, sanding rough surfaces, or curing resin under UV light. The specific steps depend on the 3D printing technology and material used.

Common Types of 3D Printing Technologies

Several 3D printing methods exist, each suited for different purposes and budgets.

Fused Deposition Modeling (FDM)

FDM is the most popular 3D printing technology for beginners and hobbyists. The printer heats a plastic filament and extrudes it through a nozzle. The material cools and hardens as the nozzle traces the object’s shape layer by layer.

FDM printers are affordable, easy to use, and compatible with many materials. They work well for prototypes, functional parts, and educational projects.

Stereolithography (SLA)

SLA uses a UV laser to cure liquid resin into solid plastic. This method produces smoother surfaces and finer details than FDM. Jewelers, dentists, and product designers often prefer SLA for high-precision work.

But, SLA prints require more post-processing. Users must wash parts in isopropyl alcohol and cure them under UV light.

Selective Laser Sintering (SLS)

SLS uses a laser to fuse powdered material, typically nylon or other polymers, into solid structures. This technology doesn’t require support structures because the unfused powder supports the object during printing.

SLS produces strong, durable parts suitable for functional testing and end-use applications. It’s more common in industrial settings due to higher equipment costs.

Direct Metal Laser Sintering (DMLS)

DMLS applies the sintering principle to metal powders. Aerospace, automotive, and medical industries use DMLS to create complex metal components that would be impossible or expensive to manufacture traditionally.

Materials Used in 3D Printing

The choice of 3D printing material affects an object’s strength, flexibility, appearance, and cost.

Thermoplastics dominate the consumer 3D printing market. PLA (polylactic acid) is biodegradable, easy to print, and ideal for beginners. ABS (acrylonitrile butadiene styrene) offers greater durability and heat resistance but requires a heated print bed. PETG combines the ease of PLA with better strength and flexibility.

Resins deliver exceptional detail and smooth finishes. Standard resins work for display models and prototypes. Specialized formulas include flexible resins, tough resins, and castable resins for jewelry making.

Metals open doors to professional applications. Stainless steel, titanium, aluminum, and precious metals can all be 3D printed. Medical implants, aerospace brackets, and custom tools often use metal 3D printing.

Composites blend plastics with carbon fiber, glass fiber, or wood particles. These materials offer unique aesthetics or enhanced mechanical properties.

Ceramics and concrete represent newer frontiers in 3D printing. Researchers and companies have printed ceramic art pieces and even concrete building components.

Each 3D printing technology works with specific material types. FDM uses filaments, SLA requires liquid resins, and SLS/DMLS work with powders. Matching the right material to the right technology is essential for success.

Popular Applications of 3D Printing

3D printing has found a home across dozens of industries. Here are some of the most impactful uses.

Rapid Prototyping remains the original and still most common application. Engineers and designers print multiple iterations of a product quickly and cheaply before committing to expensive tooling.

Healthcare has embraced 3D printing enthusiastically. Surgeons use patient-specific anatomical models to plan complex procedures. Dental labs print crowns, bridges, and aligners. Prosthetic limbs can now be custom-made at a fraction of traditional costs.

Aerospace and Automotive industries print lightweight components with complex geometries. Reducing weight saves fuel, and 3D printing enables designs that machining cannot achieve.

Consumer Products increasingly include 3D printed elements. Eyewear, footwear, and sporting goods companies use 3D printing for customization and small-batch production.

Education benefits enormously from accessible 3D printing. Students learn design thinking, engineering principles, and hands-on manufacturing skills. Teachers create visual aids and interactive learning tools.

Art and Architecture use 3D printing for sculptures, scale models, and even full-size structures. Some companies have printed entire houses using large-format concrete printers.

Spare Parts and Repairs represent a growing area. Instead of waiting weeks for a replacement part, people can download a file and print it the same day.

Benefits and Limitations of 3D Printing

3D printing offers significant advantages, but it isn’t the right solution for every manufacturing challenge.

Key Benefits

Design Freedom stands out as a primary strength. 3D printing can create geometries impossible with traditional methods, internal channels, lattice structures, and organic shapes.

Customization becomes economical. Producing one custom part costs roughly the same as producing ten identical parts. Traditional manufacturing often requires expensive molds or tooling.

Speed matters for prototypes and small batches. A designer can go from concept to physical object within hours.

Reduced Waste appeals to sustainability-focused organizations. Additive manufacturing uses only the material needed, unlike subtractive methods that cut away excess material.

Local Production cuts shipping costs and lead times. A file can travel instantly across the globe for local printing.

Notable Limitations

Production Speed lags behind traditional manufacturing for high volumes. Injection molding still wins for producing thousands of identical parts.

Material Properties don’t always match traditionally manufactured parts. 3D printed objects may have layer lines, anisotropic strength, or lower heat resistance.

Size Constraints limit most printers. Consumer machines typically handle objects up to about 8-12 inches in each dimension. Larger prints require industrial equipment or assembly.

Surface Finish often requires additional work. Layer lines remain visible on many FDM prints without sanding or chemical smoothing.

Cost Per Part makes sense for prototypes and low volumes but increases relative to traditional methods at high production scales.