Table of Contents

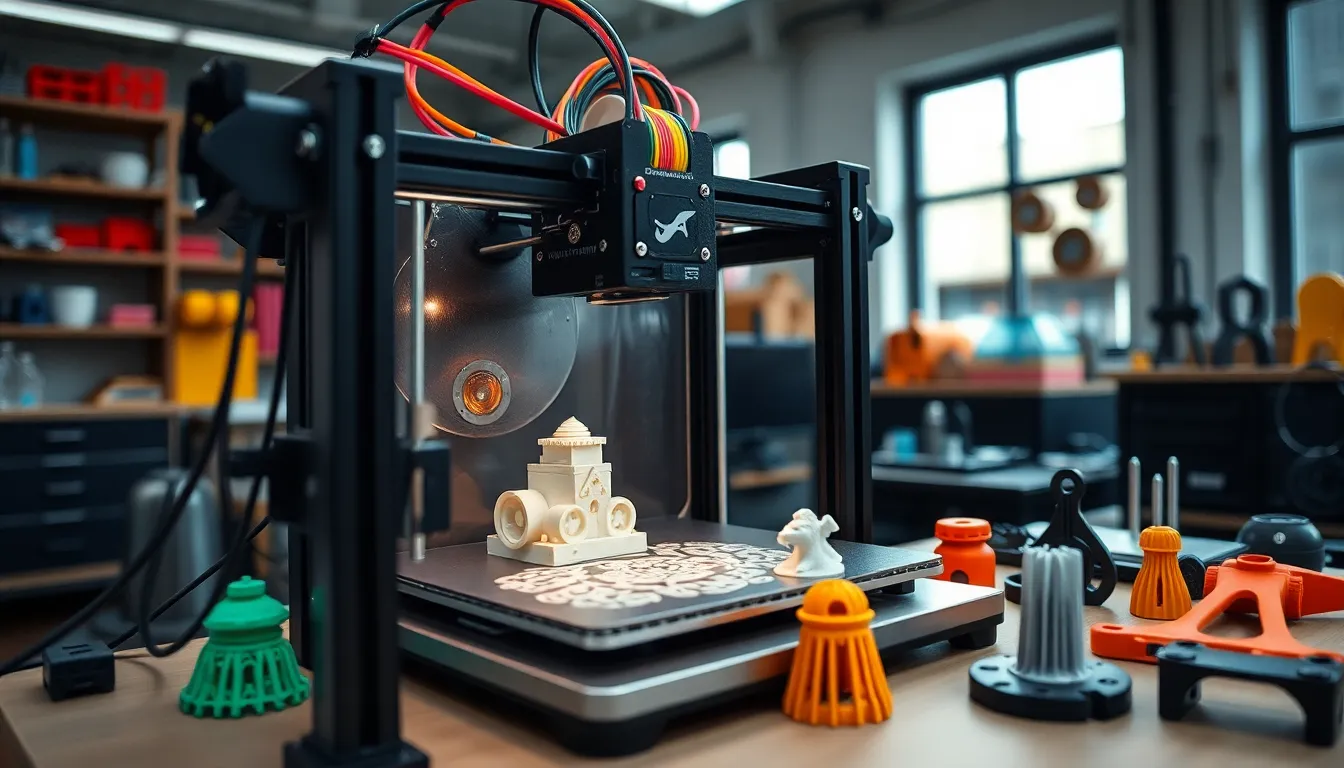

ToggleImagine a world where your wildest ideas leap off the page and into reality. Custom 3D printing makes that possible, turning dreams into tangible creations faster than you can say “Where’s my printer?” Whether it’s a quirky home décor item or a prototype for the next big invention, 3D printing opens the door to limitless possibilities.

Overview of Custom 3D Printing

Custom 3D printing presents a versatile and innovative approach to manufacturing. This technology enables the creation of tailored objects quickly, matching precise specifications. Businesses leverage custom 3D printing for a variety of applications, including prototypes, components, and artistic projects.

Several materials used in custom 3D printing include plastics, metals, and ceramics. Each material offers unique properties that enhance the final product’s capabilities. For example, PLA and ABS are common filaments used in plastic printing, while titanium is prominent in metal printing for its strength and lightweight characteristics.

In various industries, custom 3D printing leads to significant cost and time reductions. Manufacturing processes that traditionally took weeks can often be completed within days. By reducing material waste and minimizing the need for complex tooling, businesses streamline production and improve overall efficiency.

Customization options expand with advanced software that allows designers to create intricate models. These models can incorporate personal touches that resonate with individual preferences or specific business needs. Differentiation through customization becomes a competitive advantage in today’s market.

Healthcare also benefits from custom 3D printing through the creation of personalized medical devices. Custom prosthetics and dental implants tailored to an individual’s anatomy showcase the precision this technology provides. Such innovations improve patient outcomes and comfort levels.

Ultimately, custom 3D printing stands as a game-changer across numerous sectors. Its adaptability contributes to ongoing advancements, making it an essential tool for creative and industrial applications alike.

Advantages of Custom 3D Printing

Custom 3D printing offers numerous advantages that elevate its appeal across industries. These benefits include personalized designs and cost-effectiveness.

Personalized Designs

Custom 3D printing enables the creation of unique designs tailored to individual specifications. Clients access an array of customization options, allowing them to influence every detail of their projects. Industries such as fashion, architecture, and healthcare benefit significantly from this level of personalization. For example, a homeowner can design bespoke décor to match their aesthetic preferences. Furthermore, businesses leverage custom designs to develop distinct prototypes and products, enhancing brand identity. The ability to create complex geometries and intricate patterns sets custom 3D printing apart from traditional manufacturing methods.

Cost-Effectiveness

Custom 3D printing proves highly cost-effective, especially in low-volume production scenarios. This technology significantly reduces material waste by using only the necessary amount of raw materials. Companies save on manufacturing costs through streamlined processes, eliminating the need for extensive tooling and setup. Quick turnaround times also lower expenses, enabling faster time-to-market for new products. When compared to conventional methods, custom 3D printing often results in lower labor costs due to simplified workflows. Overall, this approach empowers businesses to allocate resources more efficiently while maintaining high-quality outputs.

Applications of Custom 3D Printing

Custom 3D printing serves various industries, offering tailored solutions that improve efficiency and creativity. This technology not only enhances product development but also supports personalized applications.

Healthcare

Custom 3D printing revolutionizes healthcare by creating personalized medical devices. Prosthetics designed for individual patients optimize fit and comfort, enhancing mobility. Custom dental implants utilize precise specifications, improving outcomes for dental patients. Surgical models crafted from patient data allow healthcare professionals to practice complex procedures before surgery, minimizing risks. The ability to produce low-volume, customized devices leads to reduced costs while providing significant patient-specific benefits.

Aerospace

The aerospace industry embraces custom 3D printing as a means to innovate. Complex components, such as turbine blades, benefit from lightweight materials that improve fuel efficiency. Rapid prototyping allows engineers to test designs swiftly, facilitating a faster development cycle. Parts made with 3D printing often feature intricate geometries impossible to achieve through traditional methods. Consequently, manufacturers can reduce material waste and production times while meeting stringent safety standards.

Consumer Products

Consumer products also thrive through custom 3D printing applications. Unique designs cater to individual customer preferences, enhancing user experience. Home décor items produced with 3D printers allow for personalized touches that appeal to distinct tastes. Fashion industry leaders create unique accessories using this technology, establishing brand identity in competitive markets. Custom phone cases and kitchen gadgets exemplify how everyday items can be tailored for functionality and aesthetics. By leveraging 3D printing, brands can respond quickly to market trends, meeting consumer demands effectively.

Choosing the Right Materials for Custom 3D Printing

Selecting appropriate materials is crucial for custom 3D printing projects. The right choice influences durability, flexibility, and overall aesthetics.

Common Materials Used

Various materials find use in custom 3D printing. Plastics, such as PLA and ABS, serve as popular options due to their versatility and cost-effectiveness. Metals, including aluminum and titanium, provide strength and are essential in industrial applications. Ceramics offer a unique blend of heat resistance and aesthetic appeal, making them suitable for artistic projects. Additionally, composite materials combine benefits from different substrates, enhancing overall performance.

Material Properties and Their Impact

Material properties significantly impact the final product’s performance. Strength and flexibility determine how a printed part withstands stress during use. Heat resistance affects usability in high-temperature environments. Aesthetics engage users visually, which can be crucial for products aimed at consumers. Furthermore, the material’s weight influences design, particularly in industries like aerospace where lightweight components enhance fuel efficiency. Understanding these properties allows for informed decisions during the design and printing process, ensuring successful outcomes.

Future Trends in Custom 3D Printing

Emerging technologies are shaping the future of custom 3D printing. Innovations in materials science, such as bio-based plastics and composite materials, expand design possibilities. Industries prioritize sustainability, leading to increased demand for eco-friendly printing options.

Software advancements also play a vital role. Enhanced modeling tools allow for more intricate designs at faster speeds. These tools enable designers to visualize their creations in real time, streamlining the production process. Artificial intelligence integration predicts design flaws and optimizes print settings, improving overall accuracy and efficiency.

Healthcare continues to benefit from this evolving technology. Customized implants and medical devices deliver better fit and function for patients. Moreover, bioprinting is becoming a reality, with the potential to create human tissues, significantly impacting regenerative medicine.

In aerospace, lightweight components gain attention as they enhance fuel efficiency. Striking a balance between durability and weight remains essential. Custom 3D printing speeds up prototyping cycles, facilitating quicker testing and modifications.

Consumer preferences drive trends in home décor and personal items. Individuals increasingly seek unique, tailored products that reflect their style. Custom 3D printing meets this demand, with personalized designs becoming more accessible.

Market dynamics indicate a shift toward more localized production. Businesses aim to reduce shipping costs and lead times by establishing in-house printing capabilities. This strategy enhances supply chain resilience while offering customers quicker services.

Overall, custom 3D printing is on the brink of transformation. Continuous advancements in technology, materials, and applications promise to redefine industries. As the process becomes more efficient and versatile, its impact will only grow.

Custom 3D printing stands as a beacon of innovation across various industries. Its ability to create tailored solutions quickly and affordably opens up a world of possibilities. As businesses embrace this technology, they not only enhance their product offerings but also improve operational efficiency.

With advancements in materials and software, the future of custom 3D printing looks promising. Emerging trends will likely lead to even more personalized applications and sustainable practices. This technology is set to redefine how products are designed and manufactured, paving the way for a more creative and efficient future.