Table of Contents

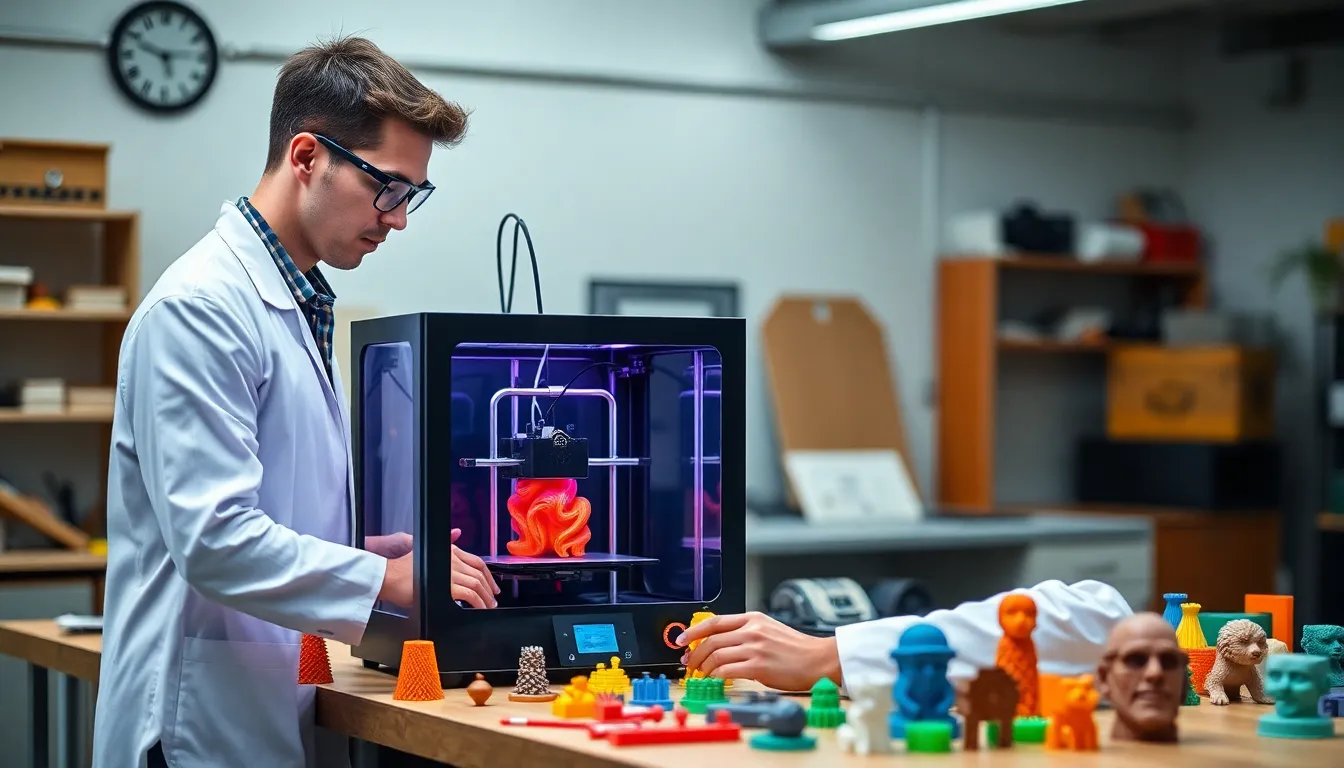

ToggleThe 3D printing industry is revolutionizing how products are made, and it’s not just for sci-fi enthusiasts anymore. Imagine a world where you can print everything from toys to medical devices right at home. Sounds like magic, right? Well, it’s not—it’s just good old technology flexing its muscles.

Overview of the 3D Printing Industry

The 3D printing industry significantly reshapes manufacturing practices, making it accessible to a broader audience. Individuals now create objects ranging from everyday goods to complex medical devices efficiently and affordably.

Definition and History

3D printing, also known as additive manufacturing, refers to the process of creating three-dimensional objects layer by layer from a digital file. This technology emerged in the 1980s, with the first patent for stereolithography filed in 1986. Since then, 3D printing has evolved rapidly, expanding into various materials like plastics, metals, and ceramics. By the 2000s, the advent of affordable desktop 3D printers made the technology more accessible for consumers and small businesses. Today, professionals and hobbyists alike utilize 3D printing in diverse fields such as aerospace, healthcare, and automotive industries, showcasing its versatility and innovative potential.

Current Market Trends

The 3D printing market is experiencing robust growth, projected to reach approximately $35 billion by 2024. Increased demand for custom products and rapid prototyping propels this growth, particularly in the healthcare and automotive sectors. Companies now prioritize sustainability, focusing on eco-friendly materials in their production processes. Moreover, advancements in technology, including enhanced printing speeds and higher-resolution outputs, are reshaping manufacturing approaches. Innovations like 3D bioprinting contribute to medical developments, such as organ and tissue regeneration. As a result, industries continue to integrate 3D printing solutions, significantly impacting their operational efficiency and product offerings.

Key Technologies in 3D Printing

3D printing encompasses several key technologies, each contributing uniquely to the industry’s growth and application. Insights into these methods reveal their significance in manufacturing.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling represents one of the most widely adopted 3D printing technologies. FDM utilizes thermoplastic materials, which are heated and extruded through a nozzle to create objects layer by layer. Common materials include ABS and PLA. Many users appreciate FDM for its cost-effectiveness and ease of use. Applications range from prototypes to final products, making it versatile across various sectors. As a result, FDM plays a crucial role in hobbyists’ workshops and professional settings alike.

Stereolithography (SLA)

Stereolithography stands out for its precision and detail. This technology employs a UV laser to cure liquid resin into hardened plastic. Users value SLA for producing intricate models with smooth surfaces, often seen in jewelry and dental applications. SLA’s rapid printing speeds also enhance efficiency. Compared to other methods, it offers superior resolution and accuracy. As such, businesses leveraging SLA achieve competitive advantages in creating highly detailed prototypes.

Selective Laser Sintering (SLS)

Selective Laser Sintering utilizes a laser to fuse powdered materials, such as nylon or metal, into solid structures. This technology excels in creating complex geometries unattainable by traditional methods. SLS enables production of functional parts rather than just prototypes, expanding its application across aerospace and automotive industries. Users benefit from the ability to produce durable items with high strength. Consequently, SLS becomes an essential option for businesses focused on custom manufacturing solutions.

Applications of 3D Printing

3D printing technology finds applications across diverse sectors, showcasing its versatility and impact on manufacturing and beyond.

Manufacturing and Prototyping

Manufacturing benefits significantly from 3D printing’s capacity for rapid prototyping. Designers utilize this technology to iterate designs quickly, reducing lead times for product testing. Many industries can create functional prototypes at a fraction of traditional costs. Customization becomes easier, allowing firms to tailor their products to meet specific consumer demands. Small batches of components can be produced without extensive tooling investments.

Medical and Dental Applications

The medical field has embraced 3D printing for its ability to produce patient-specific solutions. Surgeons use custom implants created with precise anatomical data, enhancing surgical outcomes. Dental applications have also flourished, with 3D printing making crowns, bridges, and even dentures in a streamlined process. Personalized prosthetics take advantage of this technology, improving comfort and functionality for users. Additionally, bioprinting continues to advance, with research focused on creating tissues and organs for transplantation.

Aerospace and Automotive Industries

The aerospace sector leverages 3D printing to manufacture lightweight parts that meet stringent safety and performance standards. Engineers produce complex geometries that traditional manufacturing methods can’t achieve, improving overall efficiency. In the automotive industry, 3D printing accelerates the development of prototype components, allowing rapid design changes. Companies can reduce material waste by producing only what’s necessary, which enhances sustainability practices. Both industries realize significant cost savings through the use of additive manufacturing, marking a transformative shift in production methodologies.

Challenges Facing the 3D Printing Industry

The 3D printing industry encounters several challenges that may hinder its growth and potential. These issues span intellectual property, material limitations, and regulatory hurdles.

Intellectual Property Issues

Intellectual property issues significantly impact innovation in 3D printing. Companies face challenges when protecting designs and patents, as digital files can easily be replicated. The lack of clear regulatory frameworks creates ambiguity around copyright claims and enforcement. Without robust protection, businesses are reluctant to invest in new technologies. Licensing agreements often become complicated due to the intricacies of digital content sharing. As a result, this environment can stifle creativity and slow down technological advancements.

Material Limitations

Material limitations pose another challenge. Although numerous materials are available for 3D printing, not all are suitable for every application. Certain industries require specific properties like strength, durability, or flexibility. The evolving demands for high-performance materials extend beyond current options, heavily influencing product development. Manufacturers often encounter difficulties sourcing materials that meet stringent safety standards. Additionally, the costs associated with developing and testing new materials can be prohibitive, limiting innovation and market growth.

Regulatory Hurdles

Regulatory hurdles complicate the 3D printing landscape. Various industries face strict compliance requirements related to safety and quality assurance. Healthcare applications, for instance, undergo rigorous scrutiny to ensure patient safety. Navigating these regulations can be time-consuming and costly for companies wishing to enter the market. As regulations differ worldwide, companies also struggle with varying compliance standards across regions. These challenges can hinder the rapid adoption of 3D printing technologies and slow down overall industry progress.

Future Outlook for the 3D Printing Industry

The future of the 3D printing industry holds promise, driven by technological advancements and increasing adoption across sectors.

Innovations on the Horizon

Emerging technologies in 3D printing continue to evolve and redefine manufacturing. Innovations in 3D bioprinting aim to create living tissues and organs, potentially transforming healthcare. Advances in multi-material printing allow for the production of complex items that combine different materials in a single print. Novel methods like Continuous Liquid Interface Production (CLIP) enhance speed and accuracy, making 3D printing a viable option for mass production. Improvements in software tools also simplify design processes, enabling users to create intricate models more efficiently. Overall, these advancements enhance capabilities and widen the scope of applications.

Market Growth Projections

The 3D printing market is set for significant growth, with projections estimating its value at around $35 billion by 2024. A surge in demand for customized products fuels this expansion, particularly in sectors such as healthcare and automotive. The growing emphasis on sustainability drives interest in additive manufacturing, promoting eco-friendly practices and material efficiency. A potential increase in consumer adoption further supports this growth, as more individuals seek accessible 3D printing solutions for personal use. Over the coming years, innovations in technology will likely propel the industry forward, solidifying its role in modern manufacturing.

The 3D printing industry stands at a pivotal moment in its evolution. With its potential to revolutionize manufacturing practices and enhance customization across various sectors, the future looks bright. As technology continues to advance and new materials emerge, individuals and businesses alike can look forward to a world where creating tailored solutions becomes increasingly accessible.

However, the industry must navigate challenges such as intellectual property concerns and material limitations. Addressing these issues will be crucial for unlocking the full potential of 3D printing. As it integrates more deeply into everyday life and industries, the impact of additive manufacturing will only grow, paving the way for a more innovative and sustainable future.