Table of Contents

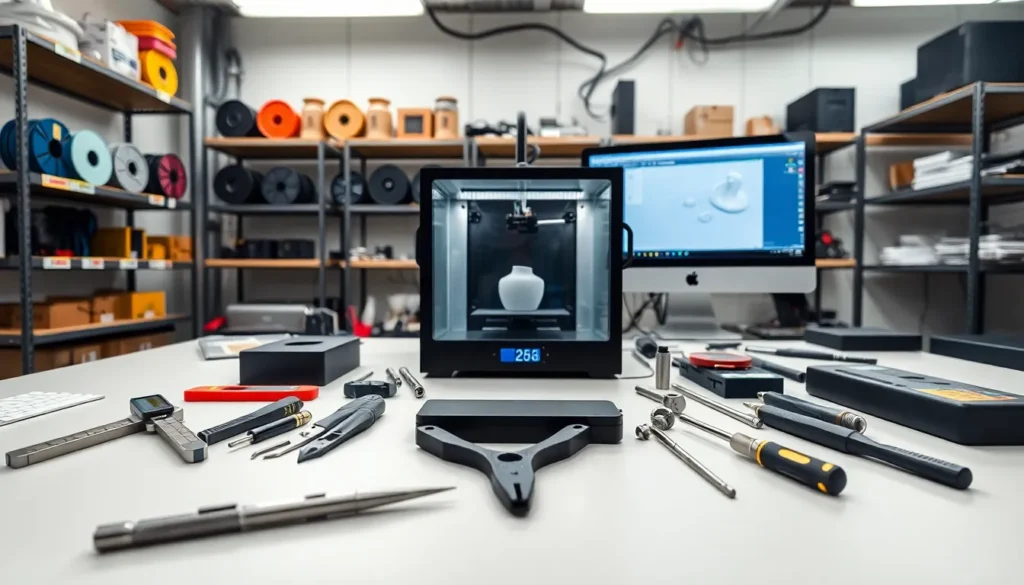

Toggle3D printing strategies can transform a frustrating hobby into a reliable production process. Whether someone prints prototypes for work or creates custom parts at home, the right approach saves time, money, and filament. Poor planning leads to failed prints, wasted materials, and hours of troubleshooting. Smart strategies prevent these problems before they start.

This guide covers the essential 3D printing strategies that deliver consistent results. Readers will learn how to select materials, optimize settings, design for success, and maintain their equipment. Each section provides practical advice that works across different printer types and skill levels.

Key Takeaways

- Effective 3D printing strategies start with choosing the right filament—PLA for beginners, ABS for durability, PETG for outdoor use, and TPU for flexible parts.

- Balancing layer height, print speed, and temperature settings improves both print quality and efficiency.

- Designing with printer limitations in mind—proper orientation, wall thickness, and tolerances—prevents failures before they happen.

- Regular maintenance like bed cleaning, belt tension checks, and nozzle care keeps your printer running reliably.

- Store filament in dry boxes or vacuum-sealed containers to prevent moisture absorption and print defects.

- Troubleshoot common issues like stringing, warping, and layer separation by adjusting temperature, retraction, and bed adhesion settings.

Choosing the Right Materials for Your Projects

Material selection forms the foundation of effective 3D printing strategies. Each filament type offers distinct properties that suit specific applications. Picking the wrong material often causes print failures or produces parts that don’t perform as expected.

PLA (Polylactic Acid) remains the most popular choice for beginners. It prints at lower temperatures, doesn’t require a heated bed, and produces minimal warping. PLA works well for decorative items, prototypes, and models that won’t face mechanical stress or heat exposure.

ABS (Acrylonitrile Butadiene Styrene) provides greater durability and heat resistance. But, it requires higher print temperatures and a heated enclosure to prevent cracking. ABS suits functional parts like phone cases, tool handles, and automotive components.

PETG combines the ease of PLA with improved strength and flexibility. It resists chemicals and moisture better than both PLA and ABS. Many users choose PETG for outdoor applications or food-safe containers.

TPU and other flexible filaments create parts that bend without breaking. These materials work for phone cases, gaskets, and wearable items. They require slower print speeds and careful retraction settings.

Beyond filament type, quality matters significantly. Cheap filament often contains inconsistent diameters and moisture contamination. These defects cause clogs, layer adhesion problems, and surface imperfections. Investing in reputable brands typically reduces failed prints and improves overall results.

Storage also affects material performance. Most filaments absorb moisture from the air, which causes bubbling and weak layer bonds during printing. Dry boxes or vacuum-sealed containers keep filament in optimal condition.

Optimizing Print Settings for Quality and Speed

Print settings directly impact both quality and efficiency. Smart 3D printing strategies balance speed against surface finish and structural integrity. Finding the right settings often requires experimentation, but some principles apply universally.

Layer Height

Layer height determines detail level and print time. Thinner layers (0.1mm) produce smoother surfaces but take significantly longer. Thicker layers (0.3mm) print faster with visible layer lines. Most users find 0.2mm offers a good compromise for general printing.

Print Speed

Faster isn’t always better. Excessive speed causes ringing (ghosting), poor layer adhesion, and dimensional inaccuracies. Start with manufacturer-recommended speeds and increase gradually while monitoring quality. External perimeters benefit from slower speeds, while infill can print faster without affecting appearance.

Temperature Settings

Both nozzle and bed temperatures affect adhesion and layer bonding. Too low causes poor layer adhesion and bed separation. Too high creates stringing, oozing, and potential heat creep. Temperature towers help identify optimal settings for each filament brand and color.

Infill Patterns and Density

Infill provides internal structure without using excessive material. For decorative prints, 10-15% infill often suffices. Functional parts may need 40-60% or higher. Grid and gyroid patterns offer good strength-to-material ratios. Some 3D printing strategies suggest using variable infill, denser near stress points and lighter elsewhere.

Retraction Settings

Proper retraction prevents stringing between print sections. The optimal distance and speed vary by extruder type. Direct drive extruders typically need 0.5-2mm retraction, while Bowden setups require 4-7mm. Too much retraction causes clogs: too little creates strings.

Design Considerations for Successful Prints

Good design prevents print failures before they happen. Effective 3D printing strategies account for printer limitations during the design phase rather than fixing problems afterward.

Orientation Matters

Part orientation affects strength, support requirements, and surface quality. Prints are weakest along layer lines, so orient parts with stress perpendicular to layers when possible. Flat surfaces against the bed produce the best finish. Overhangs beyond 45 degrees require supports, which leave marks upon removal.

Wall Thickness and Feature Size

Walls thinner than 0.8mm often fail to print properly. Most slicers default to 2-3 perimeter walls, providing adequate strength for general use. Small features like thin pins or narrow slots may not resolve correctly. Design features at least 2mm wide for reliable results.

Support Strategies

Supports allow overhangs and bridges but add print time and post-processing work. Designing with 45-degree chamfers instead of 90-degree overhangs eliminates many support requirements. Tree supports use less material than standard supports and remove more easily on organic shapes.

Tolerances for Assembly

Parts designed to fit together need clearance. A 0.2mm gap typically works for loose fits, while 0.1mm creates tighter connections. Test tolerance requirements with calibration prints before committing to large projects. Different materials shrink differently during cooling, affecting final dimensions.

Avoiding Common Design Pitfalls

Sharp internal corners concentrate stress and often crack. Fillets distribute force more evenly. Large flat surfaces tend to warp, adding ribs or slight curves improves adhesion and prevents lifting. Splitting large models into smaller pieces that glue together often produces better results than single massive prints.

Maintenance and Troubleshooting Best Practices

Regular maintenance keeps printers running reliably. Good 3D printing strategies include preventive care that avoids problems rather than just fixing them.

Routine Maintenance Tasks

Clean the print bed before each print. Oils from fingers prevent adhesion. Isopropyl alcohol removes residue effectively. Check belt tension monthly, loose belts cause layer shifting and dimensional errors. Lubricate linear rails and lead screws quarterly with appropriate grease.

Nozzles clog over time, especially with abrasive filaments like carbon fiber or glow-in-the-dark materials. Cold pulls (atomic pulls) clear partial blockages. Severely clogged nozzles need replacement. Keeping spare nozzles on hand prevents extended downtime.

Common Problems and Solutions

First layer issues cause the most failures. If prints won’t stick, level the bed, clean the surface, and adjust Z-offset. Too close squishes filament: too far prevents adhesion.

Stringing indicates temperature or retraction problems. Lower the nozzle temperature by 5-degree increments and increase retraction distance slightly.

Layer separation suggests under-extrusion or temperature issues. Check for partial clogs, increase flow rate slightly, or raise nozzle temperature.

Warping occurs when parts cool unevenly. Enclosures help with ABS. Brims add bed adhesion for PLA and PETG. Slower first layer speeds improve initial adhesion.

Firmware and Software Updates

Printer firmware and slicer software receive regular updates that improve performance and fix bugs. Update periodically but read release notes first, some updates introduce new issues. Keep working slicer profiles backed up before major upgrades.